|

As the water passes through the coarse screen (1) of the filter, there is a gradual build-up of

dirt on the fine screen (2). This causes a gradual increase in pressure differential between the

inside and outside of the screen. When the pressure drop reaches a preset level, the cleaning

cycle commences.

Cleaning Cycle

The rinse controller (8) activates the hydraulic valves (5) and piston (6), and water from the

hydraulic motor chamber (4) flows out. Pressure inside the hydraulic motor chamber, the dirt

collector (3) and inside the suction nozzles (9) drops to a very low level. This creates a pressure

gradient between the reverse side of the screen (2) (clean water) and the inside of the screen

(dirty water), opposite the suction nozzles. This backflushing operation cleans the screen ahead

of the suction nozzle.

The water and the dirt passing through the hydraulic motor (7) cause the collector to rotate, while

the piston is activated in an axial movement. The combination of the axial and rotational movement

of the nozzles means that the entire area of the fine screen is totally cleaned.

As dirt on the fine screen is washed out, the pressure gradient disappears, the rinse controller unit

closes the hydraulic valves, and the piston moves back to its original position. The system is now

ready for the next rinsing cycle. |

| NO. |

Model |

Flow

m3/h |

Screen area cm2 |

I.L.

MM |

Weight

kg |

| Flat |

Zig-Zag |

Empty |

Full |

| 1 |

WA02LE |

25 |

1530 |

4600 |

564 |

80 |

140 |

| 2 |

WA03L |

40 |

1530 |

4600 |

604 |

90 |

150 |

| 3 |

WA02LE |

40 |

1530 |

4600 |

604 |

90 |

150 |

| 4 |

WA04L |

80 |

3060 |

9200 |

748 |

104 |

184 |

| 5 |

WA04LE |

80 |

1530 |

4600 |

748 |

93 |

153 |

| 6 |

WA06 |

150 |

1530 |

4600 |

910 |

109 |

189 |

| 7 |

WA06E |

150 |

1530 |

4600 |

910 |

110 |

200 |

| 8 |

WA06L |

150 |

3060 |

9200 |

910 |

130 |

253 |

| 9 |

WA08 |

300 |

3060 |

9200 |

1176 |

152 |

292 |

| 10 |

WA10 |

400 |

4080 |

12300 |

1340 |

254 |

494 |

| 11 |

WA10L |

400 |

6100 |

18300 |

1340 |

280 |

560 |

| 12 |

WA12 |

600 |

6100 |

18300 |

1450 |

300 |

640 |

| 13 |

WA14 |

900 |

6900 |

20500 |

1532 |

435 |

865 |

| 14 |

|

|

|

|

|

|

|

| 15 |

|

|

|

|

|

|

|

| 16 |

|

|

|

|

|

|

| |

| NO. |

Model |

Flow

m3/h |

Screen area cm2 |

I.L.

MM |

Weight

kg |

| Flat |

Zig-Zag |

Empty |

Full |

| 1 |

WA02LPE |

25 |

1530 |

4600 |

450 |

80 |

140 |

| 2 |

WA03LP |

40 |

1530 |

4600 |

450 |

95 |

155 |

| 3 |

WA02LPE |

40 |

1530 |

4600 |

450 |

93 |

153 |

| 4 |

WA04LP |

80 |

3060 |

9200 |

900 |

100 |

180 |

| 5 |

WA04LPE |

80 |

1530 |

4600 |

450 |

92 |

152 |

| 6 |

WA06P |

150 |

1530 |

4600 |

450 |

108 |

188 |

| 7 |

WA06PE |

150 |

1530 |

4600 |

450 |

108 |

198 |

| 8 |

WA06LP |

150 |

3060 |

9200 |

900 |

127 |

250 |

| 9 |

WA06XLP |

120 |

4600 |

13800 |

900 |

142 |

252 |

| 10 |

WA08P |

300 |

3060 |

9200 |

900 |

144 |

284 |

| 11 |

WA08LP |

300 |

4600 |

13800 |

900 |

160 |

340 |

| 12 |

WA10P |

400 |

4080 |

12300 |

1100 |

260 |

500 |

| 13 |

WA10LP |

400 |

6100 |

18300 |

1100 |

268 |

548 |

| 14 |

WA12P |

600 |

6100 |

18300 |

1100 |

291 |

631 |

| 15 |

WA14P |

900 |

6900 |

20500 |

1270 |

315 |

745 |

| 16 |

WA16P |

1100 |

6900 |

20500 |

1270 |

435 |

885 | |

|

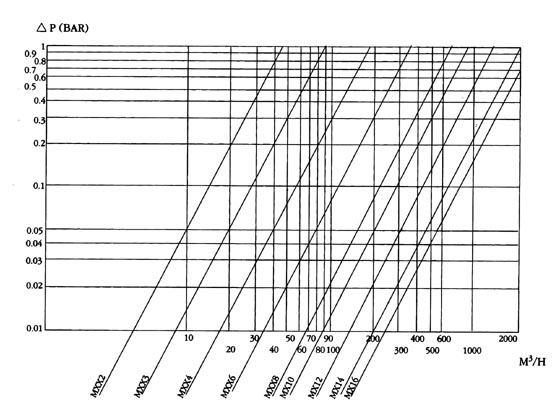

Pressure losses for various flow capacities

Screen available flat: 80, 100,120,150,200,200,400,800,1500,3000 micron.

zig-zag: 50,80,100,120,150,200 micron.

Pressure losses for maximum flow capacity: 0.2 bar.

Maximum working pressure:16 bar gauge

Minimum upstream line pressure required during rinse cycle:

All models except for "E" series:2 bar,"E" series:3.5 bar.

Maximum working temperature:65 deg C.

Approximate rinse cycle time:Piston models:8-18 sec.

Other data available on request.

|